Bystronic Press Brake

Ballscrew Guys offer refurbishment and preventative maintenance of the 5-Axis and 6-Axis Back Gauges found on Bystronic Press Brakes. The most common factor requiring back gauge service is tightening up bearing systems which have had years of use without adequate cleaning. Various types of dirt and grit, often carried over from the CNC cutting creating the 2d part blank prior to bending, gets deposited on bearing surfaces. The lubrication on the bearing surfaces causes it to stick. This coats the internal ball screw and linear way guide bearing systems, causing them to wear out prematurely. The more grit and time, the sooner the entire motion system wears out.

One of the many Manufacturers of Press Brake Back Gauges we field service. There are many variations of the Bystronic Press Brakes out there, each with different combinations of 5-Axis and 6-Axis Back Gauges installed.

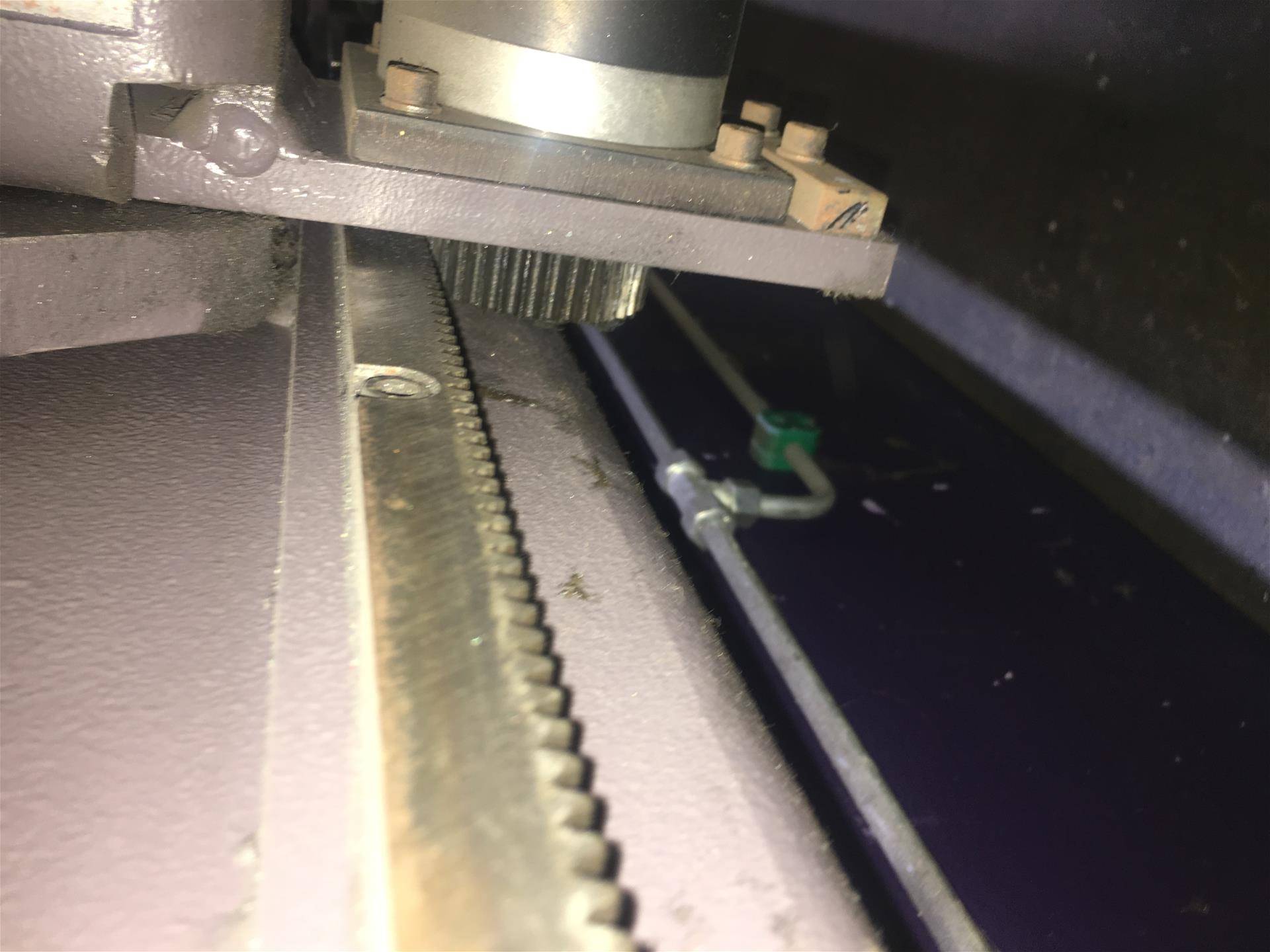

Looking at the R2-Axis Back Gauge stop. Each of these have a dedicated ball screw which controls vertical motion and positioning. Gravity often helps in positioning, even with serious ball wear within the ballscrew. After time, the screw will start to stick and stutter. It will also begin to position lower your material contacts the stop.

Here the ballscrews of the X and R screws are visible. Plus the Linear Way Guide Rail to the right. The Rack and Pinion drives are shrouded on the left. This back gauge assembly is how we found it for field inspection. Notice the dust on everything. The Linear Way Guide Rails were lubricant free. The R-Axis and X-Axis screws had a film of dirty and dusty oil on them. This Backguage is actually on the very clean side in our experience. If your back gauge is not at least this clean, you are prematurely wearing out your CNC motion system.

Look at the grit on top of the Linear Way Guide sliding block. It's on the left. This debris is being worked into the Bearing Blocks every time the axis moves. It should be regularly cleaned out.

This image shows a common sight when we inspect back gauge motion systems. Contaminated lubricant is on all the bearing surfaces. If you look on the radius curves of the bearing track, you can see the dark strip where the ball bearings ride in the race. This is debris from the steel, often residue from the cutting process creating the flat part profile, that is being crushed into the ball screw.

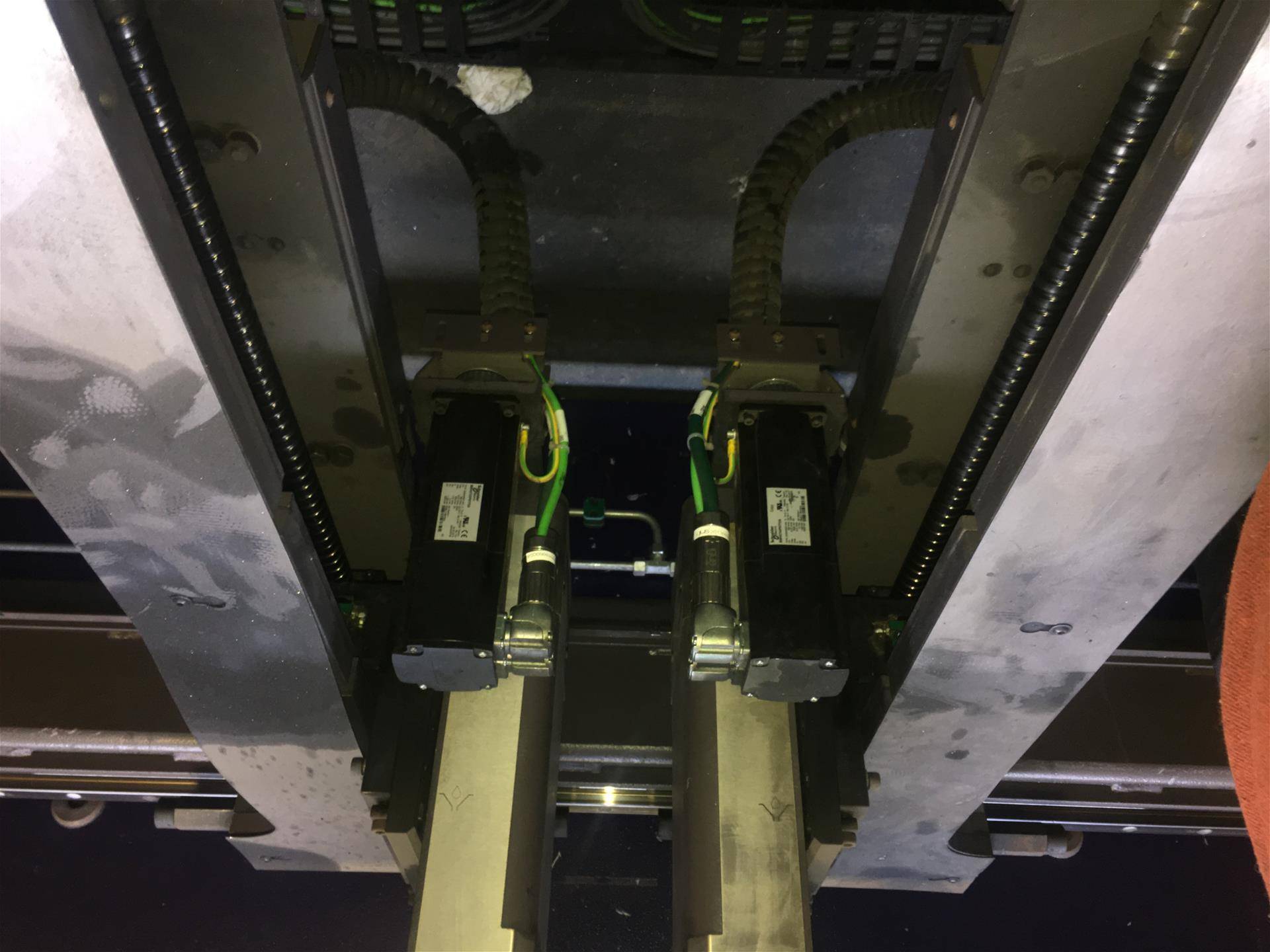

Picture of the tandem sides of the Back Gauge brought close together along the Z-Axis. Notice the black coating on the ball screws. Those should be silver in color.

The use Rack and Pinion systems for linear positioning is very low maintenance compared to ball screws. Where it excels in reliability it often lacks in accurate positioning. When positioning the two sides of a 6-Axis Back Gauge the exact location is commonly not as critical as the R and X Axis locations. Still, this assembly needs periodic toothbrush love. The entire assembly needs cleaning, especially the gear teeth on the drive cog.

Linear Way Guide Rail and Slide Blocks on the Bystronics Back Gauge need regular cleaning and maintenance. Ballscrew Guys has found that these are often overlooked and missed. Never made a real part of the regular Preventative Maintenance program. This bearing blocks are part of the back gauge system in maintaining a consistent exact material stop location. If these blocks have bearing wear or damage, they can wiggle on the rail, being a contributing factor in solving tolerance issues on bend location.